SCADA Systems

HMI and SCADA

HMI

HMI is the acronym for Human Machine Interface which, simply put, is an interface between a user and a machine. HMI is a term specific to manufacturing and process control systems. An HMI provides a visual representation of the status of a control system with real-time data acquisition.

HMI’s can also act as the centralized control unit for manufacturing lines as they are usually equipped with non-volatile memory containing data recipes, can execute event logging and event triggering, and can provide video feed for status monitoring. For a manufacturing line to be integrated with an HMI, it must first be connected to a Programmable Logic Controller (PLC) or Motion Controller. It is the PLC/Motion Controller that takes the information from the machine sensors and converts it into Boolean algebra to communicate with the HMI.

A Human Machine Interface or HMI is defined as a feature or component of a certain device or software application that enables humans to engage and interact with machines. Some examples of common Human Machine Interface devices that we encounter in our daily lives include touchscreens and keyboards.

HMIs utilized in the industrial context are mostly screens or touchscreens that connect users to machines, systems or devices. Factory operators use HMIs to control and automate machinery, as well as their production lines. HMIs can be simple screen displays mounted on machines in the factory, advanced touchscreens, multi-touch-enabled control panels, push buttons, computers with keyboards, mobile devices or a tablet.

The Evolution of Human Machine Interfaces

Engaging with Machines Using Batch Processing

During the 1950s, batch processing was the dominant mode of engaging with machines, in terms of entering input.

Batch processing required a user to specify all the details and sequences of a task, usually using a punch card. This punch card was fed into the machine. The machine evaluated the punch card and delivered the results. Batch processing was not an efficient mode of human-machine engagement since the technique lent itself to a high probability of error.

The development of command line interfaces followed batch processing. Command line processing is a more interactive way for users to engage with machines and allows the user to issue direct commands to the machine. This is done through entering successive lines of text, using a program which accepts the text. This was the dominant mode of engaging with machines during the 1960s.

Graphical User Interfaces (GUIs) made up the next phase of human-machine engagement. These interfaces allow end users to engage with machines using rich graphical elements such as windows, buttons and icons. This is referred to as the WIMP model (window, icon, menus and pointer). The actual devices used to engage included keyboards and devices such as the mouse.

As the use of computers and technology increased in modern society, there was a need for more sophisticated levels of human-machine engagement. This lead to the development of touchscreens and graspable user interfaces that allow users to engage with virtual objects using a physical handle.

SCADA

SCADA (supervisory control and data acquisition) is a category of software applications for controlling industrial processes, which is the gathering of data in real time from remote locations in order to control equipment and conditions. SCADA provides organizations with the tools needed to make and deploy data-driven decisions regarding their industrial processes.

One of the most commonly used types of industrial control system, SCADA can be used to manage almost any type of industrial process.

SCADA systems include hardware and software components. The hardware gathers and feeds data into field controller systems, which forward the data to other systems that process and present it to a human-machine interface (HMI) in a timely manner. SCADA systems also record and log all events for reporting process status and issues. SCADA applications warn when conditions become hazardous by sounding alarms.

Components of a SCADA system

SCADA systems include components deployed in the field to gather real-time data, as well as related systems to enable data collection and enhance industrial automation. SCADA components include the following:

- Sensors and actuators. A sensor is a feature of a device or system that detects inputs from industrial processes. An actuator is a feature of the device or system that controls the mechanism of the process. In simple terms, a sensor functions like a gauge or meter, which displays the status of a machine; an actuator acts like a switch, dial or control valve that can be used to control a device. Both sensors and actuators are controlled and monitored by SCADA field controllers.

- SCADA field controllers. These interface directly with sensors and actuators. There are two categories of field controllers:

- Remote telemetry units, also called remote terminal units (RTUs), interface with sensors to collect telemetry data and forward it to a primary system for further action.

- Programmable logic controllers (PLCs) interface with actuators to control industrial processes, usually based on current telemetry collected by RTUs and the standards set for the processes.

- ? Communication infrastructure. This enables SCADA supervisory systems to communicate with field devices and field controllers. This infrastructure enables SCADA systems to collect data from field devices and to control those devices.

- SCADA is sometimes compared with the industrial internet of things (IIoT), and while there is considerable overlap, the two terms are different. SCADA vendors tend to provide more complete, monolithic systems with tight integration across levels and devices, while IIoT vendors are likely to provide greater interoperability and more options for deploying systems and devices across an organization

Features of SCADA systems

Although SCADA systems may include special features for specific industries or applications, most systems support the following features:

- Data acquisition is a foundation of SCADA systems; sensors collect data and deliver it to field controllers, which, in turn, feed data to the SCADA computers.

- Remote control is achieved through the control of field actuators, based on the data acquired from field sensors.

- Networked data communication enables all SCADA functions. Data collected from sensors must be transmitted to SCADA field controllers, which, in turn, communicate with the SCADA supervisory computers; remote control commands are transmitted back to actuators from the SCADA supervisory computers.

- Data presentation is achieved through HMIs, which represent current and historical data to the operators running the SCADA system.

- Real-time and historical data are both important parts of the SCADA system, as they enable users to track current performance against historical trends.

- Alarms alert SCADA operators to potentially significant conditions in the system. Alerts can be configured to notify operators when processes are blocked, when systems are failing, or when other aspects of SCADA processes need to be stopped, started or adjusted.

- Reporting on SCADA system operations can include reports on system status, process performance and reports customized to specific uses.

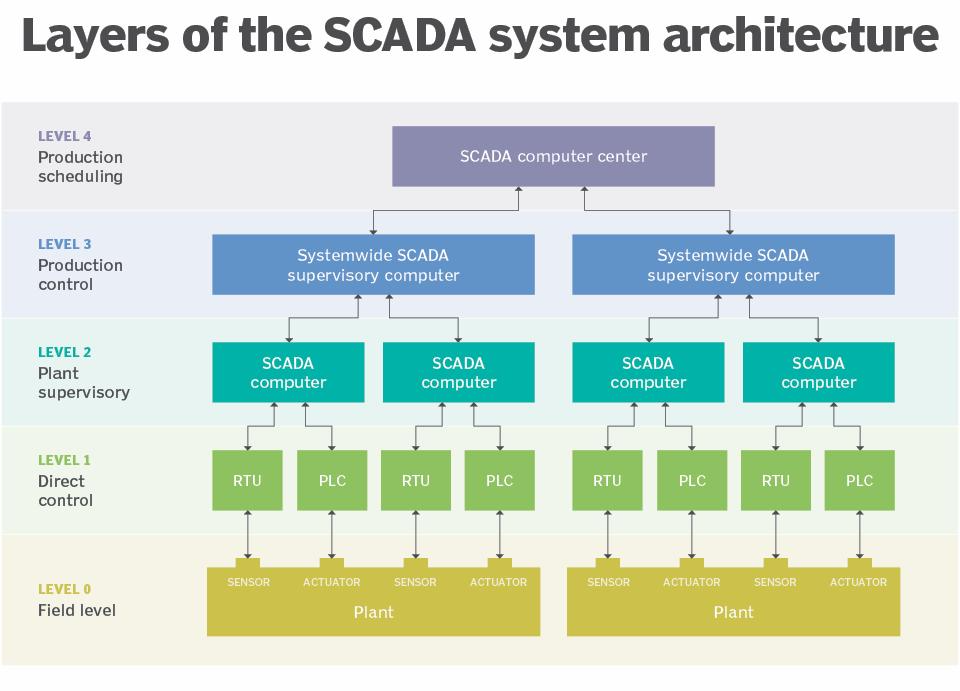

SCADA architecture

- Level 0. The field level includes field devices, such as sensors, used to forward data relating to field processes and actuators used to control processes.

- Level 1. The direct control level includes local controllers, such as PLCs and RTUs, that interface directly with field devices, including accepting data inputs from sensors and sending commands to field device actuators.

- Level 2. The plant supervisory level includes local supervisory systems that aggregate data from level controllers and issue commands for those controllers to carry out.

- Level 3. The production control level includes systemwide supervisory systems that aggregate data from Level 2 systems to produce ongoing reporting to the production scheduling level, as well as other site or regionwide functions, like alerts and reporting.

- Level 4. The production scheduling level includes business systems used to manage ongoing processes.

Evolution of SCADA architecture

The history of SCADA parallels the history of enterprise computing. The earliest SCADA systems were implemented in large industrial enterprises, as they first started to integrate mainframe computing resources with industrial processes.

As computing, networking and process monitoring and control systems have improved, SCADA evolved through the following four stages:

- First generation: Monolithic systems. SCADA systems implemented in the 1960s and 1970s usually incorporated RTUs at industrial sites connected directly to mainframe or minicomputer systems, usually also on-site or connected over wide area network

- Second generation: Distributed systems. SCADA systems took advantage of wide availability of proprietary local area networks and smaller, more powerful computers during the 1980s to enable greater sharing of operational data at the plant level and beyond. However, the lack of open networking standards prevented interoperability across SCADA product vendors.

- Third generation: Networked systems. SCADA systems depended on greater interoperability provided by industry acceptance and incorporation of standard network protocols during the 1990s. SCADA systems could be scaled more easily, as enterprises were able to integrate systems across their own industrial infrastructure, while using a wider variety of devices and systems.

- Fourth generation: Web- or IIoT-based systems. SCADA systems began appearing in the early 2000s as SCADA vendors embraced web software development tools to enable transparent interoperability and access via universally available interfaces, like web browsers running on handheld devices, laptops and desktop computers.

As cloud computing increasingly dominates the enterprise computing world, it is also changing SCADA systems. SCADA systems can be scaled faster and more easily by allocating cloud computing resources as needed for surges and reducing those resources when demand drops.

Modern SCADA Systems

Modern SCADA systems allow real-time data from the plant floor to be accessed from anywhere in the world. This access to real-time information allows governments, businesses, and individuals to make data-driven decisions about how to improve their processes. Without SCADA software, it would be extremely difficult if not impossible to gather sufficient data for consistently well-informed decisions.

Also, most modern SCADA designer applications have rapid application development (RAD) capabilities that allow users to design applications relatively easily, even if they don’t have extensive knowledge of software development.

The introduction of modern IT standards and practices such as SQL and web-based applications into SCADA software has greatly improved the efficiency, security, productivity, and reliability of SCADA systems.

SCADA software that utilizes the power of SQL databases provides huge advantages over antiquated SCADA software. One big advantage of using SQL databases with a SCADA system is that it makes it easier to integrate into existing MES and ERP systems, allowing data to flow seamlessly through an entire organization.

Historical data from a SCADA system can also be logged in a SQL database, which allows for easier data analysis through data trending.

What is the Difference Between HMI and SCADA?

Supervisory Control and Data Acquisition (SCADA) and HMI are closely related, and often referred to in the same context since they are both part of a larger industrial control system, but they each offer different functionality and opportunities. While HMIs are focused on visually conveying information to help the user supervise an industrial process, SCADA systems have a greater capacity for data collection and control-system operation. Unlike SCADA systems, HMIs do not collect and record information or connect to databases. Rather, HMI provides an effective communication tool that functions as part of, or alongside, a SCADA system.

SCADA stands for “Supervisory Control and Data Acquisition.”

These are used for monitoring and controlling large areas, typically a full site or plant. SCADA systems are a combination of many systems including sensors, RTUs or Remote Terminal Units, and PLCs.

Data from all of these systems is then sent to the central SCADA unit. That SCADA unit has its own HMI. This is why a lot of people get confused and think SCADA and HMI are one and the same.

That HMI or “Human Machine Interface” unit on the SCADA can monitor and control anything that is connected to it. In conclusion, HMI can be part of SCADA but SCADA cannot be part of a HMI. It’s that simple.

At each location there was a PLC that was connected to some sensors to monitor water flow, pressure, and other things, and it was able to run and control the pump itself.

The remote SCADA unit was connected to the PLC system and allowed operators to control and monitor each pump station from the main plant. I’m sure you can imagine how much time and labor a good SCADA system can save a company

An HMI is essentially a user control station, usually in the form of a touchscreen or a screen with some buttons attached. They are typically tied to a machine or process.

SCADA and HMI systems are here to collect and display certain data, respectively. A PLC, as an industrial computer, serves as a bridge between the process and its control. As such, a PLC is often used in conjunction with SCADA systems and HMIs. An HMI is something that’s ever-present in every type of industry and even in our homes in a form of a monitor or a tablet.

As the technology progressed, new types of HMI and SCADA systems are made. The prime example of modern HMI is touchscreen, which offers a lot of flexibility for the operator. With the growing trends in industrial hardware, both SCADA and PLCs got some boost. PLCs are now able to perform the most complex logical tasks, while SCADA systems are much more versatile and are able to collect a huge chunk of data.